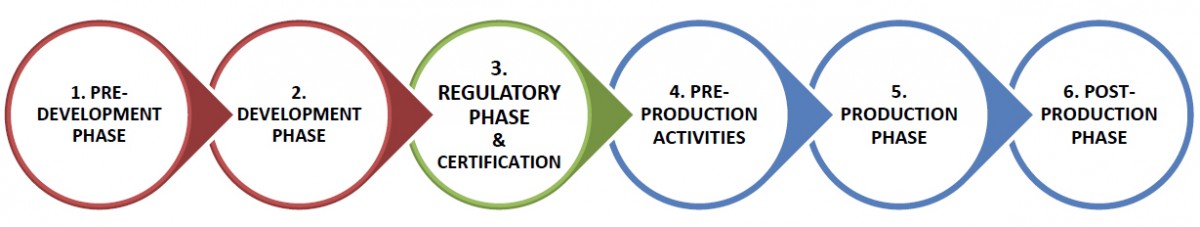

PRODUCT DEVELOPMENT AND PRODUCTION PHASES

1. PRE-DEVELOPMENT PHASE

Meeting with customer

The first meeting is important. We check all possibilities for cooperation. It is recommended that customers have a clear idea of what they expect so we can check all possibilities of cooperation. We can also help with our own ideas or add any suggestions to existing. Basic cooperation stages are also set in this phase.

Idea to concept creation

All ideas from the customer must be transformed into the concept. Our expertise in the field of cosmetics and food supplements is utilized in this step.

Checking for possibilities of concept realization

The realistic conclusion must be made to see if the customer’s expectations can be turned into practice and end products. Our expertise are novel, innovative, and complex projects, so we tend to find solution for every customer’s demands.

Working team: Work is done by Herbana employees under the supervision of the chief research officer. Other experts might be included in the project if necessary.

Working time: 1 – 2 months (Working time depends on the project and is orientation value only – for usual projects)

The idea is important!

Any idea can be turned into a concept, but good concepts are only created if the idea has a solid foundation, a vision, and some enthusiasm.

2. DEVELOPMENT AND RESEARCH PHASE

Product formulation

The composition of the final product is defined in this stage. Complete concepts are formulated into final products. We have available a wide range of raw materials and in-depth knowledge of active ingredients effects. Our expert advice and proper raw material combinations are suggested to the customers. We specialize in the development of products in the field of natural and organic cosmetics. Finished products can also be officially certified.

Packing selection

The selection of primary packing is selected based on product composition and in cooperation with the customer. The steps of product formulation and packing selection are interdependent. In some cases, the customer already has his own selected packing, in this case, the formulation of the product can be adjusted to be compatible with it. Our suggestions are functional, recyclable, and user friendly packs.

Design creation

External looks of the products and/or brand started to be created in this step if not already done so. Herbana Company does not create designs directly. All of the services are usually done by customers themselves or are outsourced to qualified professionals.

Lab tests / sample products

Customers get sample products for testing or possible corrections. It might take just one or in some cases more sample tests to achieve a final version of the formulation.

Confirmed sample / formulation

Final product composition and an approved pack are needed to finish the development phase. When customers confirm the final version of the product/s, lab work is done and activities on paperwork begin.

Product specification / technical sheet

All cosmetics or food supplement products have master document done with basic information including composition sheet, data for label, specifics, etc. The Technical (manufacturing) sheet with instructions for the production phase is also prepared. Exact data with all the documentation is needed for the next, regulatory phase.

Working team: Work is done by Herbana employees under the supervision of the chief research officer. Other experts might be included in the project if necessary.

Working time: 1 – 12 weeks (Working time depends on the project and is orientation value only – for usual projects)

Natural and organic products

We specialize in the development of natural and organic cosmetics. Production is regulated in accordance with the ECOGEA standard for natural and organic products, which is comparable to other EU standards in this area. Food supplements and food products can be certified according to the EU certification for organic food – SI-EKO-001.

3. REGULATORY PHASE

Product information file / safety assessment

All cosmetic products need to have the documentation prepared in accordance with Regulation (EC) No. No 1223/2009. In consist from part A and part B. Responsible person for the product/s is also set via the European notification portal (CPNP).

Label creation (content)

All the data needed for the products label creation are prepared for the customer. The final version of the label needs to be added to the product information file.

Claims for products

Complete selection of allowed claims (if any) is reviewed and proposed to the customer for marketing purposes.

CPNP registration and product entry

All cosmetic products on the EU market need to be notified via the cosmetic products notification portal (CPNP). Composition sheets and labels are also uploaded to the CPNP in this step.

Working team: Work is done by ECOGEA Institute experts in cooperation with Herbana employees. ECOGEA may use external accredited laboratory services to get all necessary analyses if needed (microbiology, heavy metals, stability tests, etc). All documents are prepared in accordance with EU regulations.

Inspections and control: Herbana company is regularly controlled by Slovenian health inspectors together with inspectors for natural and organic products (SI-EKO-001 and ECOGEA).

Dietary supplements and food: Different regulation applies for food products and cosmetics. Dietary supplements and food do not need the same product information file as cosmetics. Focus on dietary supplements and food is on correct claims, correct label creation, and certificates of analysis with supporting documentation.

Working time: 1 – 6 weeks (Working time depends on the project and is orientation value only – for the usual projects)

Documentation and responsible person

We can prepare all the documentation you need for your products in accordance with EU regulations. We can also be a contractually responsible person for you and represent you before the health inspection, which checks the suitability of the products.

4. NATURAL OR ORGANIC CERTIFICATION OF PRODUCTS (OPTIONAL)

Natural or organic certification

All cosmetic products can be certified in accordance with the natural and organic standard for cosmetics, cleansing products, and fragrances via ECOGEA Institute. All food supplements or other food products can be certified via an accredited certifying body (for example SI-EKO-001).

2 in 1 solution

All cosmetic products can be certified together with product information file / safety assessment preparation during the regulatory phase. The cost of certification is significantly reduced in comparison to making both processes separately.

Working team: Work is done by ECOGEA Institute experts. With the customer’s consent, ECOGEA Institute can collect all necessary information directly from the manufacturer (Herbana). In this way, the client avoids the additional bureaucratic work of obtaining all the needed documentation. Herbana company is certified for the production of natural and organic products in accordance with the ECOGEA standard.

Working time: 1 – 4 weeks (Working time depends on the project and is orientation value only – for the usual project)

Organic certificate - Certificates of efficiency

Your products can obtain organic certificates and various efficiency certificates, which will strengthen your competitive position in the market.

5. PRE-PRODUCTION ACTIVITIES

Ordering of raw materials

All raw materials are ordered from reliable suppliers. Ordering for production usually requires ordering from a few different suppliers. We need to take into account that each supplier has its own lead times and this can prolong the delivery time. All supporting documentation needs to be received with arriving raw materials. Usual documentation includes certificates of analysis, safety data sheets, specifications, allergen list if any, and others.

Ordering of packing materials

All packings are ordered from reliable suppliers. All supporting documentation needs to be received. Primary packing materials are the ones in direct contact with the product. Usually, these are for example jars, bottles, cans, pouches, etc. Usual documentation for primary packs includes a declaration of conformity, certificates of analyses, specifications, usage level statements (cosmetics, food or pharma), and others. Secondary packs are usually cardboard product boxes, plastic blisters, etc. Tertiary packs include combined product packs and/or transport boxes.

Checking of the compliance of used materials

All incoming raw materials and packing are checked by qualified receiving control manager on site. Customers are informed if any kind of non-compliance is registered during the receiving of goods. All activities to solve the issue (if possible) start immediately in coordination with supplier and customer.

Important:

All raw materials and packings need to be delivered from suppliers to our manufacturing facility/warehouse before production starts. Production of the product does not start until all raw materials and packing are in stock.

Working team: Work is done by Herbana employees under the supervision of chief technology officer in coordination with the plant manager and logistic manager on-site.

Working time: 1 – 6 weeks (Working time depends on the project and is orientation value only – for the usual project)

Raw materials and packaging

Quality and reliable suppliers of raw materials and packaging are crucial. We also help customers in this step if necessary, as we have a wide network of suppliers.

6. PRODUCTION PHASE

Pre -preparation of raw materials

Pre-preparation of raw materials is needed in some cases. Activities in this step usually include filtering, grinding, premixing, and other similar processes, to achieve suitable input raw material for the next steps of the production.

Weighting of raw materials

The weighting of raw materials is the first “real” step of the production phase. This needs to be done for each product. A quantitative product specification sheet is used for exact quantities.

Melting of raw materials

Most of the production procedures require some kind of melting of raw materials that can be incorporated with other ingredients in later steps. A typical example of the melting procedure is the melting of the beeswax and mixing it with various liquid oils.

Mixing, homogenization, and stabilization of mixtures

This is one of the most important steps in the production. Each product needs to be mixed with appropriate mixing parameters. All products have their exact mixing parameter program set during the development phase. Homogenization is done with special equipment and mixing techniques. Properly homogenized product is the key goal of each production. It impacts product visual appearance and stability. Almost all products require stabilizing procedures during manufacture. It may vary from slow mixing of bulk to time set settling in special vessels. This operating manufacturing step is finished when the product is properly mixed, homogenous, and stable, and so ready for further manipulation.

Preparing of bulks

Products are stored in so-called bulk tanks for easier manipulation. In some cases products need to settle in tanks for some period of time before being manipulated further.

Quality control / checking of control parameters

All products need to have pre-defined control parameters check. These are usually color, odor, appearance, pH, viscosity, etc. These need to be checked during the manufacturing phase.

Filling into packings and capping

All products are filled in some kind of packing, such as bottles, jars, cans, pouches, etc. Bulks are filled using appropriate filling equipment and techniques. Capping or sealing of these packs is done in the same step.

Labelling, LOT/batch printing

Labeling is done after the filling step. Information such as batch, the expiry date is also printed on the packs in this step.

Working team: Work is done by Herbana employees under the supervision of chief technology officer in coordination with the plant manager and on-site responsible technician.

GMP: All products are manufactured in accordance with good manufacturing practices.

Working time: 2 – 4 weeks (Working time depends on the project and is orientation value only – for the usual project)

Production processes are important

Proper and well-coordinated manufacturing processes are very important for a quality end product. At Herbana, we make sure that your product is manufactured according to the correct parameters.

7. POST-PRODUCTION PHASE

Warehouse services

We can store all excess raw materials after production in our warehouse/logistics center. Final products are also stored in the tempered warehouse till dispatch/pick-up. Our logistics complex offers fast and reliable handling of all goods.

Sorting and packaging in transport boxes

All products are properly sorted and packed into suitable transport boxes. Each transport box must be labeled and marked with Lot/batch number and expiry date.

Pelletizing / preparation for transport

Pallets are prepared before dispatch. Extra protection is added to the pallet to protect the product during transport.

Shipping / dispatch

Various options are available. We can organize transportation within our network or customers can pick-up the pallets themselves (EXW).

Working team: Work is done under the supervision of chief technology officer in coordination with the plant manager, logistic manager, and on-site technicians.

Working time: up to 1 week – usually a day or two (Working time depends on the project and is orientation value only – for the usual project)

8. AFTER-SALE SUPPORT

Guarantee

All products developed and manufactured by Herbana have a complete quality guarantee. If any complication occurs we work closely with our customers to find solutions for any issues that may occur. Our experts always find proper solutions.

Professional help

In some cases, additional consulting services are required regarding the products. It might be from the area of regulations, raw materials, documentation, marketing strategies, or other related fields. Our goal is long term business cooperation, so we always help our customers also after the sale.

Working team: Work is done by Herbana employees in coordination with the responsible person. Other experts might be included in the project if necessary.

Important: If the customer is manufacturing the products in Herbana company according to their own formulation, they are responsible for the final stability of the products!

Working time: depends on the issue and project.

Post-production support is important

Good post-production support is needed, as only in this way can a comprehensive solution be provided to customers and is an additional guarantee of satisfaction.

Descriptions and a range of the brand’s products can be viewed in the Herbana online store. We can make similar products for you. Product specifications, certificates of analysis, and all necessary documentation are available. All products are manufactured and certified in accordance with strict internationally recognized ECOGEA standard.